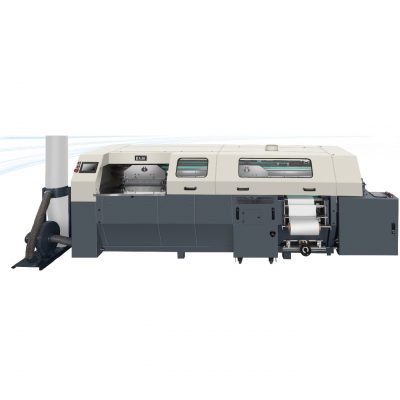

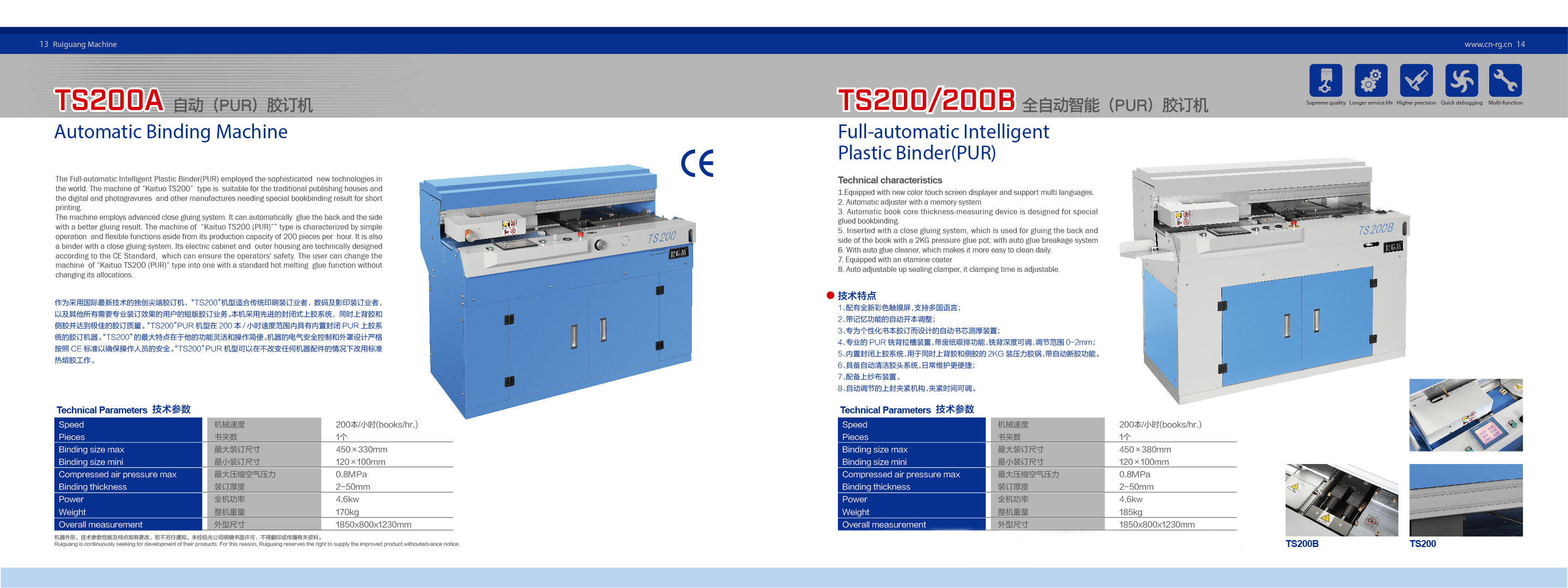

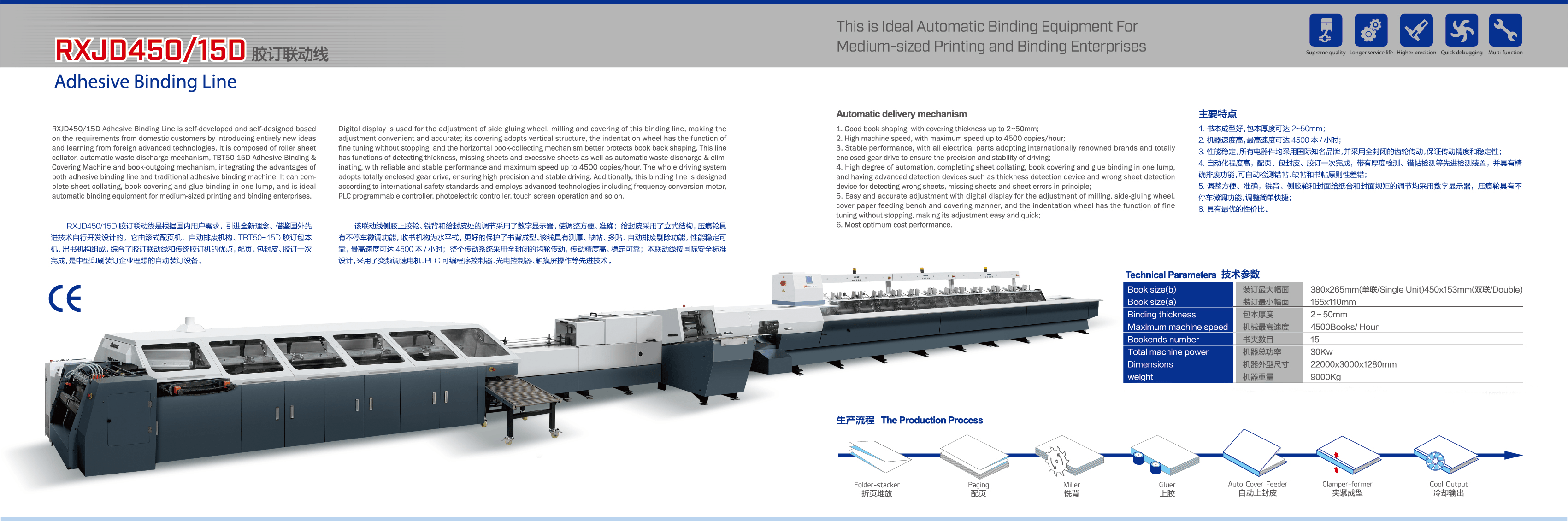

HL-TBT50/10D 10 夹钳式全自动完美装订机 The cover feeder adopts a vertical structure to ensure accurate and reliable cover supply. The embossing wheel is provided with the non-stop fine adjustment function. The delivery mechanism adopts a horizontal mode for better protection of book back forming. This binder can used for either thread or perfect binding, so it’ s an ideal device for perfect or thread bookbinding in various printing house and university printing offices.

The binder adopts many advanced technologies like speed control by frequency variation, plc, two closed loop temperature control, photo electrical identification, automatic detection control and touch screen. The whole transmission system adopts the fully-en- closed gear to ensure stable and reliable transmission. The back glue is provided with before/after glue stop function and the adjustment of milling back flute, glue pot and cover feeder is provided with digital display function.

The Whole Transmission System Adopts The Fully-enclosed Gear To Ensure Stable And Reliable Transmission.

- Vertical type stacking mechanism

Covering adopts vertical type stacking structure, with the function of digital display for raising and lowering of the paper bench and the adjustment of covering manner.

- Holding and striking mechanism

The holding and striking mechanism is controlled by several cams, ensuring ideal shaping effect, with binding thickness up to 2~50mm.

- Book-collecting mechanism

Horizontal book-falling of book-collecting mechanism better protects the shaping quality of book back; And the stacking mechanism has its stacking height ranging from 20~100mm.

- Back-gluing pot

Back-gluing pot has the glue-ending function, minimizing the glue threads.

- Electricity

The electricity is designed according to international safety standards, with visualized and straightforward interface as well as easy operation; The interface has a failure display function easy to clean troubles and an automatic maintenance & prompt function, ensuring the normal running of the equipment.

详细数据: automatic perfect book binding machine

| 姓名

Maximum size of book |

Parameter

380×265(单联/Single Unit) or 450×153 |

| Minimum size of book

Covering thickness |

(双联/Double)165x110m 2-50mm |

| Maximum binding speed | 4000书籍/小时 |

| Binder number

Total power of machine |

10

13.5千瓦 |

| Overall dimensions of machine weight | 4900x1920x1490mm

4500公斤 |

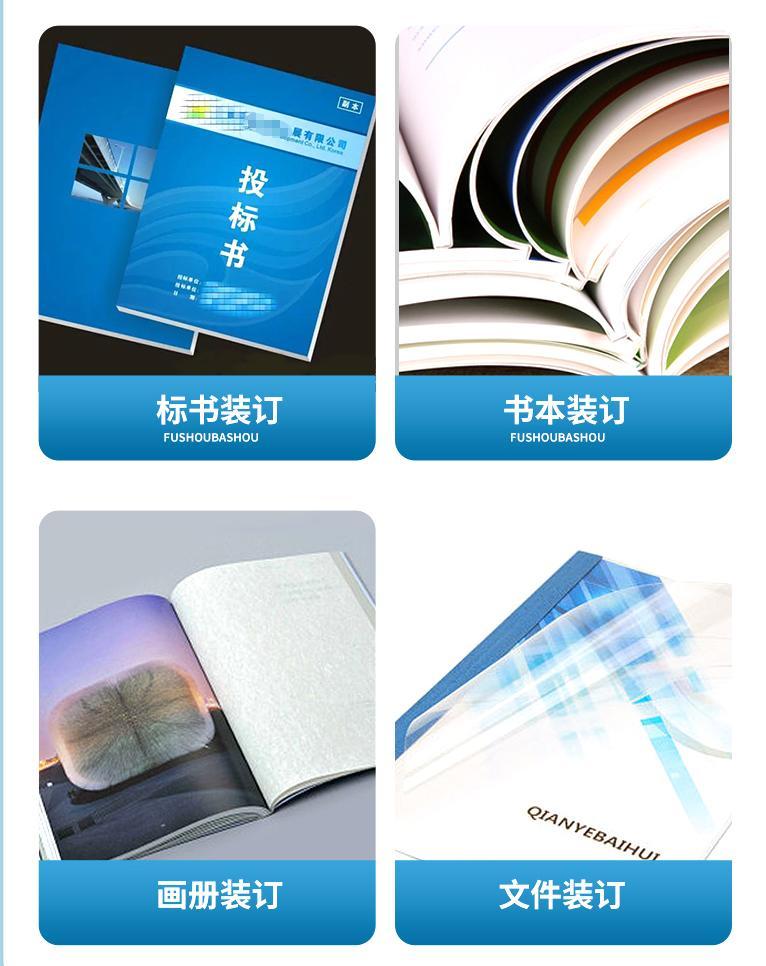

胶书装订机样品

视频

关于我们

Zhejiang Haoly Limited 结合了极具竞争力的价格, 印后机的创新技术和长期的出口经验, 印刷机,和包装机, 和快速印刷机。我们是您印刷包装行业的最佳选择.

过去十年, 兰溪金华机器公司专注线缝练习本机器, 直纹和片材, 软装、精装书。可制造全自动练习本制作机, 练习簿标尺机, 书籍缝纫机, 机壳内, 硬皮封面机, 三边修剪器, 骑马订机, 胶装机, 和其他印后机.

我们还可以提供各种印刷和包装机械, 例如

1. 印后机: 切纸机, 层压机, 压痕模切机, 烫金机, 折纸机, 纸张配页机, 纸张打孔机, 鸡眼机

2. 印刷机: 胶印机, 预压机, 柔印机, 证卡印刷机

3. 快速印刷机: 小切纸机, 数码压痕机, 小型胶装机.

4. 纸制品制造机: 涂胶机文件夹, 纸盒机, 纸袋机, 纸杯机, 信封制造机

我们是一家实际的工厂和制造商,从事印后机和包装机系列的贸易超过 10 年.

1. 30 多年生产经验 品质优良. 我们所有的机器都有CE证书.

2. 在同级别切纸机质量中具有竞争力的价格.

3. 周到的售前售后服务. 任何问题, 请随时联系我们.

对于大多数订单, 付款条件是 30% 生产前提前T/T, 余额 70% 应在交货前付款. 我们也接受其他方式,如信用证, 西联汇款等.

1. 乌斯利 ,大多数机器稳定且易于操作, 借助视频和说明, 您可以快速学习如何操作.

2. 如果还是无法操作, 我们提供在线培训和视频指导

3. 如果您需要派遣工程师, 请联系我们进行详细咨询

浩力机

浩力机