Não apenas adequado para os papéis de capa dura comuns, mas também adequado para o couro e outros materiais.

Custo mais barato:

Cola de proteína microtérmica seca rapidamente, sem deformação e menor custo.

Operação fácil:

O sistema de dobra automática de borda automática retribuída dobra duas arestas automaticamente ao mesmo tempo.

Detecção de fibra óptica de alta velocidade Controle o comprimento e a posição do papel alimentando com precisão.

Multi-funções:

Unidade de Herater Independente Homermal Impermeável pode usar a cola de proteínas (quente) e látex branco (frio).

O preenchimento quantitativo da água automaticamente e o rendimento da água pode ser ajustado.

Velocidade de aplicação de cola de escolaridade.

Reflexão da luz suave e posição central.

Tampas duras padrão e três espinhas estão disponíveis por alteração e adicione os guias da coluna rapidamente.

O cortador de canto pode cortar quatro cantos padrão em diferentes espessuras de papelão sem ajuste.

Guias de papel sobem e descem e controlados pela válvula de pé pneumática.

Instalação fácil:

O modelo do tipo dividido pode entrar na porta do elevador e na porta do escritório.

A parte de cola pode ser escolhida para definir no lado esquerdo/direito, O modelo padrão está do lado esquerdo.

Equipado com rodízios de alta carga, conveniente para ajuste de nível, consertar e mover a máquina.

| Colagem quente: Espalhe a cola na parte de trás da capa uniformemente. | |

|

✽ Rolo de cola de alta precisão torna a cola ell-distribuída.

✽ A liga de cobre fez o Roller de aplicação de cola e o reservatório de cola tornar a condução de calor rápida e bem distribuída.

✽ O dispositivo de enchimento de água quantitativo preenche a quantidade adequada de água de acordo com as condições de uso que evitam a cola de secagem e solidir.

✽ Unidade de aquecedor impermeável homotérmico independente, cola de proteína, Jelly Glue e látex branco podem ser usados separadamente.

✽ A espessura da cola pode ser ajustada.

|

|

| Sucção e posição: Amarrado ao papelão e coluna com papel de capa. | |

|

✽ Flexível e rápido para mudar a versão diferente dos guias de coluna, fácil de criar muitos casos totalmente decorados.

✽ Assistência de sucção torna o material da capa posicionado com precisão, e evite as bolhas quando a tampa colada com papelão.

✽ É fácil ver a posição da coluna por mesa leve com a linha positiva central, que rotula a linha de referência em malha para variedade de formatos

✽ O medidor traseiro humanizado pode ser ajustado e fixado para garantir o mesmo tamanho de cada capa dura acabada.

|

|

| Cortador de canto: Corte quatro cantos do papel de capa. | |

|

|

|

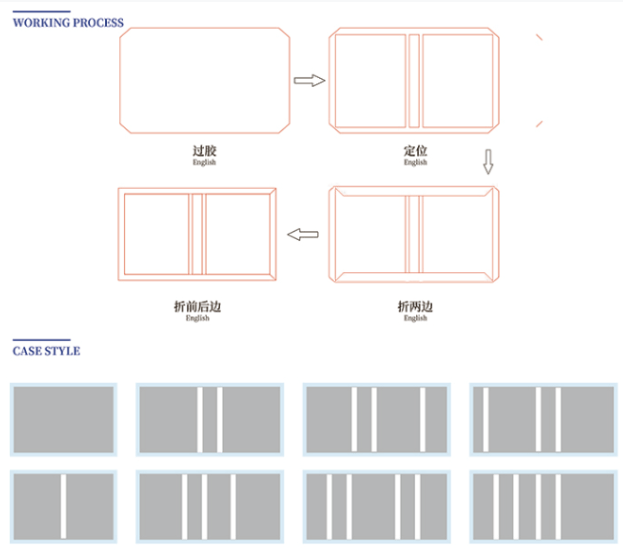

| Dobragem de borda automática: Coloque o papelão ligado na pasta Edge e as bordas serão dobradas automaticamente. | |

|

✽ As bordas da direção da alimentação serão dobradas após colocar os cartões ligados na pasta Edge com detecção de reflexo óptico.

✽ O tamanho e a posição da dobra da borda podem ser ajustados.

✽ A pressão dobrável pode ser ajustada para adaptar diferentes espessuras dos cardboards.

|

|

|

Rolos de cola são feitos de liga de cobre que garantem a cola bem distribuída. A cola de animais é derretida por bandeja de água, e a velocidade de cola pode ser ajustada. |

|

A detecção de fibra óptica de alta velocidade controla o comprimento e a posição do papel alimentando com precisão, O sistema de dobra automática de borda automática retribua dobra e pressione duas bordas automaticamente por vez. |

|

Adicionar a água automaticamente e a quantidade de água pode ser ajustada. |

|

Levante e abaixe os rolos dobráveis superiores por dispositivo de tipo de plug-in para ajustar a lacuna para diferentes espessuras de carbetos. |

|

O tamanho da borda de vedação pode ser ajustado |

|

Altere rapidamente e adicione guias de coluna para fazer vários produtos de capa dura.

Pode produzir livros de encadernação dobráveis e calendários com acessórios simples. |

|

A tabela de vácuo fornece grande sucção que garante que o papel de capa não seja fácil de mover.

Caixa de luz suave para registro preciso de capas coladas por reflexão especular. |

|

O cortador de canto pode cortar quatro cantos padrão em diferentes espessuras de papelão sem ajuste. |

|

Equipado com rodízios de alta carga, É conveniente para ajustar de nível, consertar e mover a máquina. |

Dados Detalhados:

|

Modelo |

SK840A |

SK960A |

|

máx.. Tamanho do produto |

840x480mm |

960x480mm |

|

Tamanho da mesa de trabalho |

980x466mm |

1090x466mm |

|

Largura de colagem |

500milímetros |

500milímetros |

|

Largura da borda da capa dura |

840milímetros |

960milímetros |

|

Espessura de papelão |

1.5 - 4mm |

1.5 - 4mm |

|

Espessura do papel de cobertura |

80 - 400gsm |

80 - 400gsm |

|

Fonte de energia |

220V |

220V |

|

Gás de máquina |

0.6MPa |

0.6MPa |

|

Peso da máquina |

500kg |

545kg |

|

Dimensões da máquina |

1650x1460x1110mm |

1760x1460x1110mm |

|

※ Fonte do ar da máquina para selecionar, Equipamento reservado interface de traquéia de φ8mm. |

||

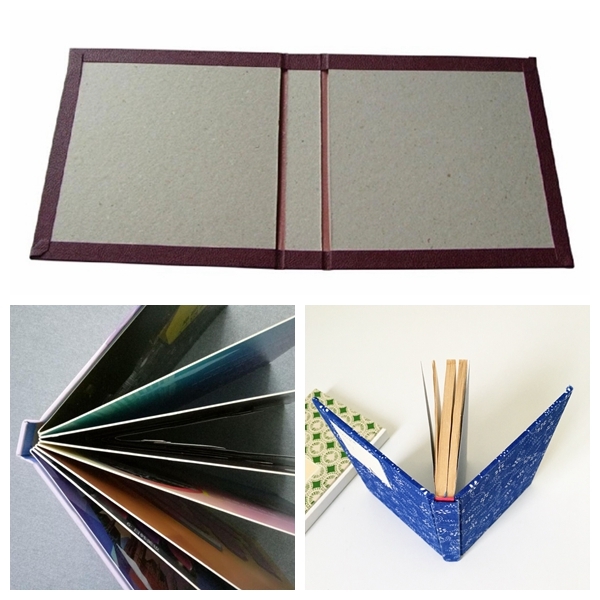

Amostra para Máquina de fabricação de estojo de livro

Vídeo

Sobre nós

Zhejiang Haoly Limitada combina preço extremamente competitivo, tecnologias inovadoras e experiência de exportação de longa data na máquina Post press, impressora,e máquina de embalagem, e máquina de impressão rápida. Somos a sua melhor seleção para as indústrias de impressão e embalagem.

Nos últimos dez anos, Lanxi Jinhua Machine Company está se concentrando na máquina para livros de exercícios costurados com fio, governado e folhado, livro de capa mole e dura. Pode fabricar máquina de fazer livro de exercícios automática completa, máquina de decisão do livro de exercícios, máquina de costura livro, invólucro na máquina, máquina de fazer capa dura, aparador de três lados, máquina de costura de sela, máquina de encadernação de cola, e outra máquina de pós-impressão.

nós também podemos fornecer tipos de máquina de impressão e embalagem, como

1. máquina de pós-impressão: máquina de corte de papel, máquina de laminação, máquina de vincar e cortar, máquina de estampagem a quente, máquina de dobrar papel, máquina de agrupamento de papel, máquina de perfuração de papel, máquina de ilhós

2. Impressora: máquina de impressão offset, máquina de pré-impressão, Máquina de impressão flexográfica, máquina de impressão de cartão

3. máquina de impressão rápida: pequeno cortador de papel, máquina de vincar digital, pequena máquina de encadernação de cola.

4. Máquina de fazer produtos de papel: pasta coladora, máquina de caixa de papel, máquina de saco de papel, máquina de copo de papel, máquina de fazer envelopes

Somos uma fábrica e fabricante reais com comércio na linha de máquina de pós-impressão e máquinas de embalagem por mais de 10 anos.

1. 30 anos de experiência em produção com boa qualidade. Todas as nossas máquinas têm certificado CE.

2. Preço competitivo no mesmo nível de qualidade das máquinas de corte de papel.

3. Serviço atencioso de pré-venda e pós-venda. Alguma pergunta, Por favor se sinta livre para nos contatar.

Para a maioria dos pedidos, condições de pagamento é 30% T/T adiantado antes da produção, o equilíbrio 70% deve ser pago antes da entrega. E também aceitamos outras formas como L/C, Wetern Union etc.

1. Uauslly ,a maioria das máquinas é estável e fácil de operar, Com a ajuda de vídeos e instruções, você pode aprender rapidamente como operar.

2. Se ainda não puder operar, Oferecemos treinamento on-line e instruções em vídeo

3. Se você precisar despachar um engenheiro, entre em contato conosco para consulta detalhada

Máquina Haoly

Máquina Haoly