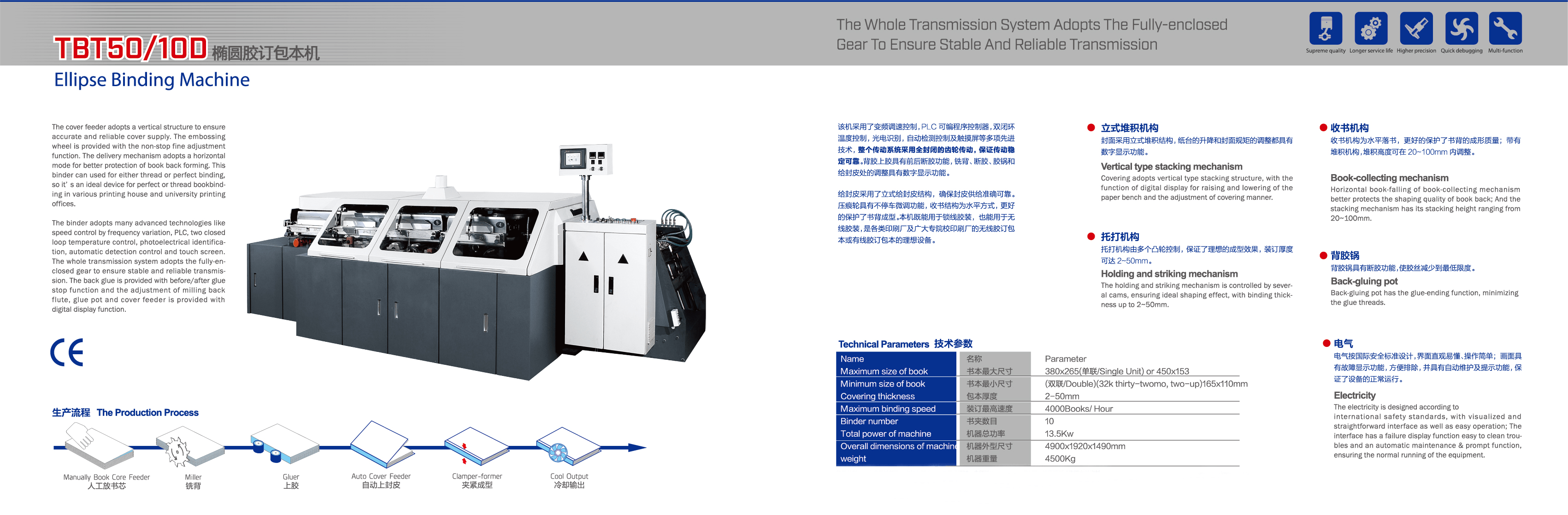

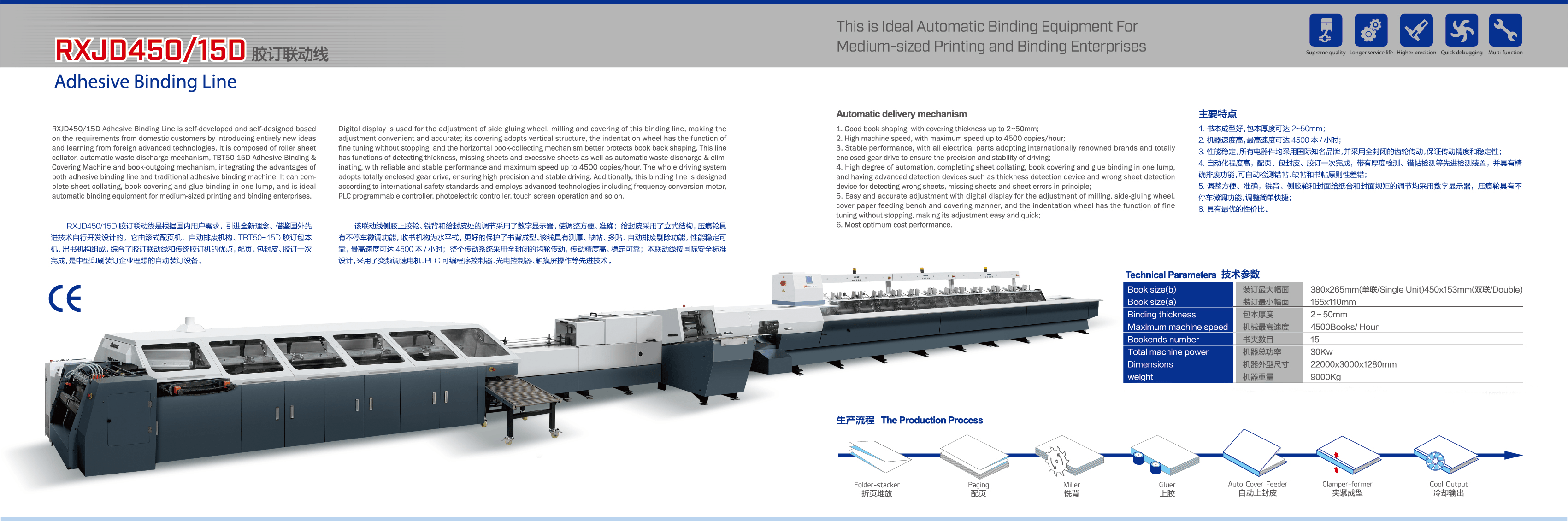

HL-TBT50/10D 10 clamps full automatic perfect book binding machine The cover feeder adopts a vertical structure to ensure accurate and reliable cover supply. The embossing wheel is provided with the non-stop fine adjustment function. The delivery mechanism adopts a horizontal mode for better protection of book back forming. This binder can used for either thread or perfect binding, so it’ s an ideal device for perfect or thread bookbinding in various printing house and university printing offices.

The binder adopts many advanced technologies like speed control by frequency variation, PLC, two closed loop temperature control, photo electrical identification, automatic detection control and touch screen. The whole transmission system adopts the fully-en- closed gear to ensure stable and reliable transmission. The back glue is provided with before/after glue stop function and the adjustment of milling back flute, glue pot and cover feeder is provided with digital display function.

The Whole Transmission System Adopts The Fully-enclosed Gear To Ensure Stable And Reliable Transmission.

- Vertical type stacking mechanism

Covering adopts vertical type stacking structure, with the function of digital display for raising and lowering of the paper bench and the adjustment of covering manner.

- Holding and striking mechanism

The holding and striking mechanism is controlled by several cams, ensuring ideal shaping effect, with binding thickness up to 2~50mm.

- Book-collecting mechanism

Horizontal book-falling of book-collecting mechanism better protects the shaping quality of book back; And the stacking mechanism has its stacking height ranging from 20~100mm.

- Back-gluing pot

Back-gluing pot has the glue-ending function, minimizing the glue threads.

- Electricity

The electricity is designed according to international safety standards, with visualized and straightforward interface as well as easy operation; The interface has a failure display function easy to clean troubles and an automatic maintenance & prompt function, ensuring the normal running of the equipment.

Detailed Data: automatic perfect book binding machine

| Name

Maximum size of book |

Parameter

380×265(单联/Single Unit) or 450×153 |

| Minimum size of book

Covering thickness |

(双联/Double)165x110m 2-50mm |

| Maximum binding speed | 4000Books/ Hour |

| Binder number

Total power of machine |

10

13.5Kw |

| Overall dimensions of machine weight | 4900x1920x1490mm

4500Kg |

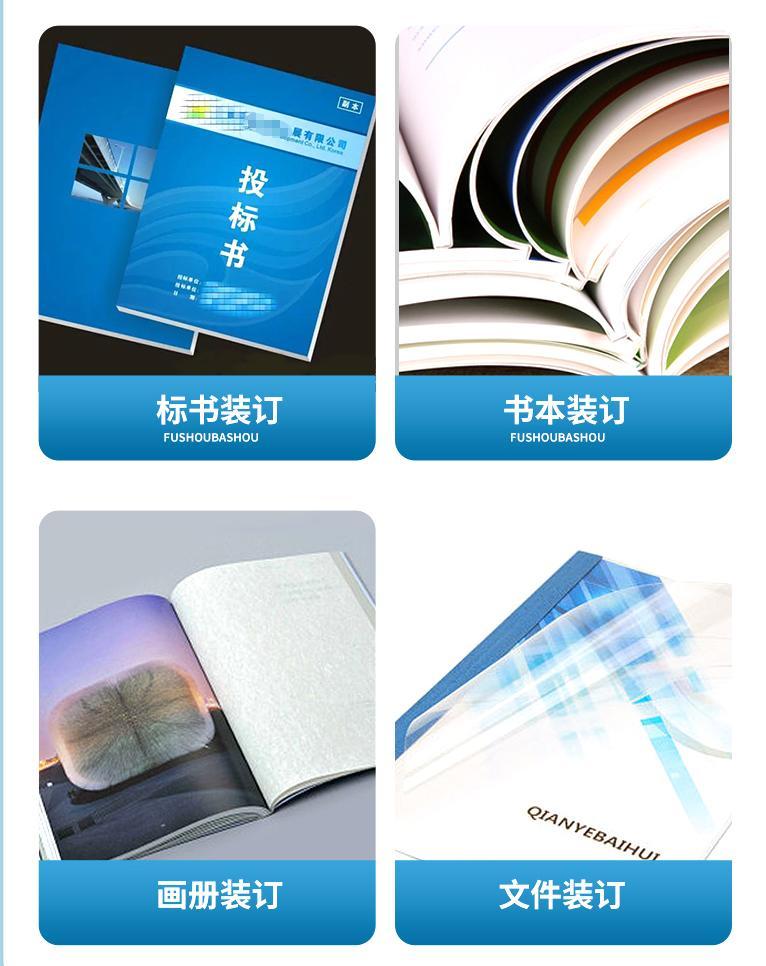

Sample for Glue Book Binding Machine

Video

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine.We are your best selection for printing and packaging industries.

In past ten years, Lanxi Jinhua Machine Company is Focusing on machine for wire-stitched exercise books, ruled and sheeting, soft and hard cover book.Can manufacture full automatic exercise book making machine, exercise book ruling machine, book sewing machine, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machine.

we also can provide kinds of printing and packaging machine, such as

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine