SX180/51 Digital-controlled Fully Automatic Sewing Machine consists of sheet-separation, sheet-turning, transferring, positioning, sewing, thread-cutting, book-separation, threadend-cutting and computer-controlled system.The whole machine is produced in one piece.

Unit functions, features:

High speed and high precision: top speed of 180 per minute, the machine has a fully sealed CAM control b ox, control box filled with lubricating oil inside,smooth operation, durable, drive locking wire saddle precisi on needle group work. The book on the locking wire saddle post through the structure of the synchronous belt gauge pull up complete accurate positioning.

Intelligent: All working process from feeding, transferring, fault alarming, sewing to delivery is monitored and controlled by touchscreen

Fault alarm: Machine automatically stops when fault alarm blares

Stick with automatic error detection function “optional”;

Memory: It stores sewing program for future use.

Automatic changeover: Use touchscreen to automatically change job size

Automatic changeover: Automatic changeover via touchscreen. By pressing the START on touchscreen, the convoy belt, sheet-turning gear,chains and wheels move to working position automatically.

Signature separation: signatures are separated by blower and mechanical arms.

Automatic Sheet-turning: eight computer-controlled sheet-turning gears

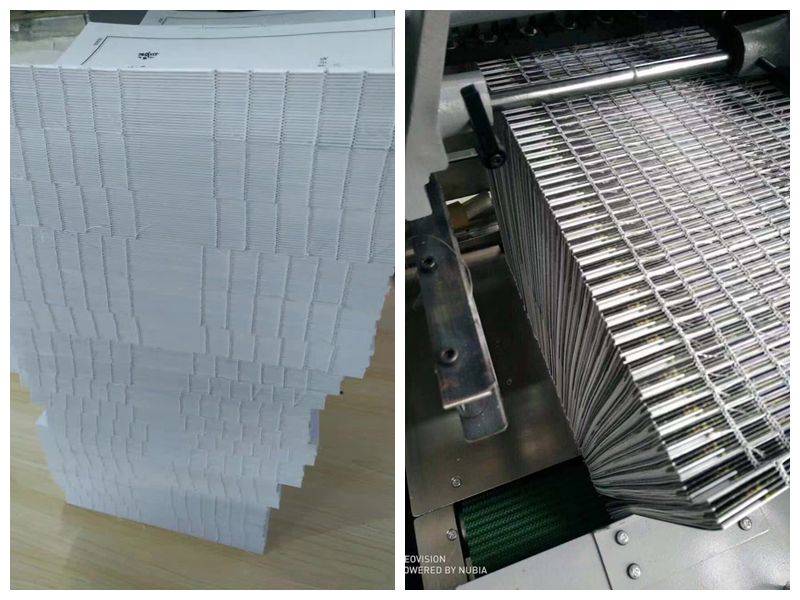

Signature-transferring: transferring open signatures through guide rail transferred by chain hook into transferring wheel,The speed of transferring wheel is automatically adjusted.

Book-separation and thread-cutting: Separate books and cut the end of thread to about 10mm. Straight and cross sewing: Needles of diameter(¢1.6mm)with 19mm between each other provides high sewing quality. Sewing gears are cam-controlled. It’s easy to change between straight and cross way of sewing.

Lubrication: Central lubrication system. Alarming in want of oil. Timing lubrication system.

High speed and high precision: top speed of 180 per minute, the machine has a fully sealed CAM control box, control box filled with lubricating oil inside, smooth operation, durable, drive locking wire saddle precision needle group work. The book on the locking wire saddle post through the structure of the synchronous belt gauge pull up complete accurate positioning.

Using two robots and four synchronous belt racks jammed, do double this paper and transport under more stable and reliable;

Intelligent: All working process from feeding, transferring, fault alarming, sewing to delivery is monitored and controlled by touchscreen

Fault alarm: Machine automatically stops when fault alarm blares

Stick with automatic error detection function “optional”;

Memory: It stores sewing program for future use.

Automatic changeover: Use touchscreen to automatically change job size

Automatic changeover: Automatic changeover via touchscreen. By pressing the START on touchscreen, the convoy belt, sheet-turning gear,chains and wheels move to working position automatically.

Signature separation: signatures are separated by blower and mechanical arms.

Automatic Sheet-turning: eight computer-controlled sheet-turning gears

Signature-transferring: transferring open signatures through guide rail transferred by chain hook into transferring wheel,The speed of transferring wheel is automatically adjusted.

Book-separation and thread-cutting: Separate books and cut the end of thread to about 10mm. Straight and cross sewing: Needles of diameter(¢1.6mm)with 19mm between each other provides high sewing quality. Sewing gears are cam-controlled. It’s easy to change between straight and cross way of sewing.

Lubrication: Central lubrication system. Alarming in want of oil. Timing lubrication system.

Detailed Data:

| Max. mechanical speed | 180 cycles/min | Min signature sewed | 2Post |

| Max. size (H x L) | 510x320mm | Available openings | 4 above, 4below +1 lap |

| Min. size (H x L) | 120x75mm | Rated power | 5kw |

| Number of stitch positions | 12 groups | Standard voltage | 400V, 50 Hz, 3 phases |

| Stitch lenght | 19 mm | Air consumption (external supply) | max. 1.0m3/min at 8bar |

| Needle diameter | ¢1.6 mm | Net weight | 4500Kg |

| Single signature thickness | 0.5~1.5mm | Measures | 2970×1650×1850mm |

| L H S

Max. size 320 510 1.5mm Min. size 75 120 0.5mm |

AUSCP SX180/51 | ||

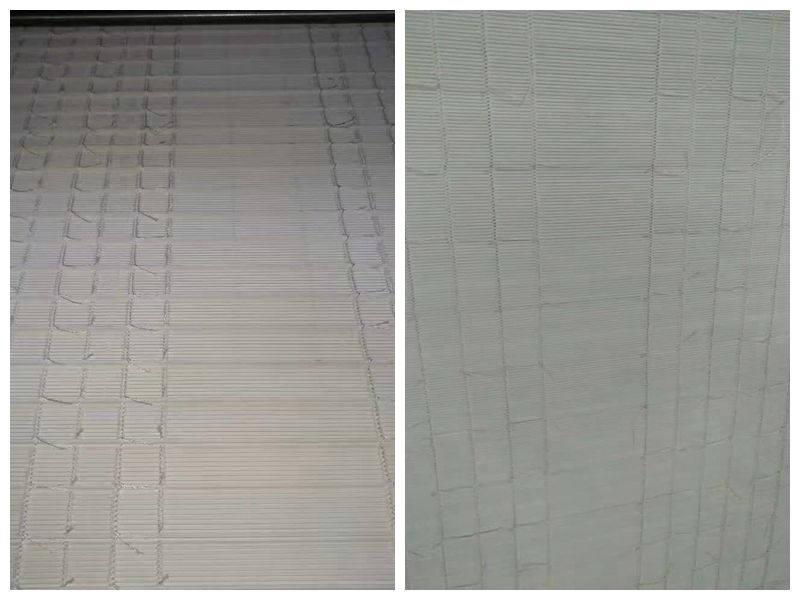

Sample for Automatic Book Sewing Machine

Video

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine.We are your best selection for printing and packaging industries.

In past ten years, Lanxi Jinhua Machine Company is Focusing on machine for wire-stitched exercise books, ruled and sheeting, soft and hard cover book.Can manufacture full automatic exercise book making machine, exercise book ruling machine, book sewing machine, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machine.

we also can provide kinds of printing and packaging machine, such as

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine