Not only suitable for the common hard cover papers, but also suitablt for the leather and other materials.

Cheaper cost:

Microthermal protein glue dry quickly, no deformation and lower cost.

Easy operation:

Reciprocating automatic edge fold system fold two edges automatically at one time.

High speed optical fibre detection control the length and position of the paper feeding accurately.

Multi-functions:

Independent homothermal impermeable herater unit can use both protein glue (hot) and white latex (cold).

Quantitative filling the water automatically and the water yield can be adjusted.

Stepless glue application speed.

Soft light reflection and center position.

Standard and three spines hard covers are available by change and add the spine guides quickly.

The corner cutter can cut four standard corners on different thickness of cardboard without adjustment.

Paper guides go up and down and controlled by pneumatic foot valve.

Easy installation:

Split type model can enter into elevator door and office door.

Glue part can be choosed to set on the Left/Right side, the standard model is on the Left side.

Equipped with high load casters, convenient to level adjusting, fixing and moving the machine.

| Hot gluing: Spread the glue on the back of the cover uniformly. | |

|

✽ High accuracy glue roller makes the glue ell-distributed.

✽ Copper alloy made glue application roller and glue reservoir make the heat conduction fast and well distributed.

✽ Quantitative water filling device fill proper amount of water according to the use conditions which avoid the glue from drying and soliding.

✽ Independent homothermal impermeable heater unit, protein glue, jelly glue and white latex can be used separately.

✽ The thickness of the glue can be adjusted.

|

|

| Suction and Position: Bound the cardboard and spine with cover paper. | |

|

✽ Flexible and fast to change the different version of spine guides, easy to create many fully decorated have cases.

✽ Suction assistance makes the cover material positioned accurately, and avoid the bubbles when the cover glued with cardboard.

✽ It’s easy to see the spine position by soft light table with center positing line which labels the reference meshed line for variety of formates

✽ Humanized back gauge can be adjusted and fixed to ensure the same size of each finished hard cover.

|

|

| Corner cutter: Cut four corners of the cover paper. | |

|

|

|

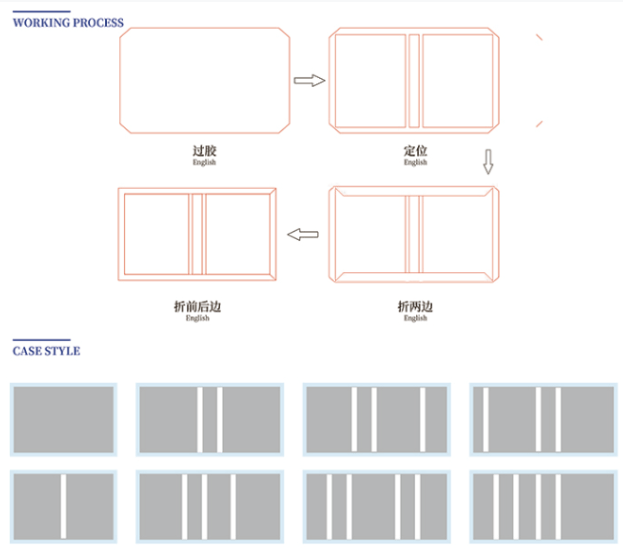

| Automatic edge folding: Put the bound cardboard into the edge folder and the edges will be folded automatically. | |

|

✽ Edges of feed direction will be folded after put the bound cardboards in to the edge folder with optical reflex detection.

✽ The size and position of the edge folding can be adjusted.

✽ The folding pressure can be adjusted to adapt different thickness of the cardboards.

|

|

|

Glue rollers are made of copper alloy which ensure the glue well distributed. Animal glue is melted by water tray, and the glue speed can be adjusted. |

|

High speed optical fiber detection controls the length and position of the paper feeding accurately, reciprocating automatic edge fold system fold and press two edges automatically at a time. |

|

Adding the water automatically and the water quantity can be adjusted. |

|

Lift and lower the top folding rollers by Plug-in type device to adjust the gap for different thickness of cardboards. |

|

The size of the sealing edge can be adjusted |

|

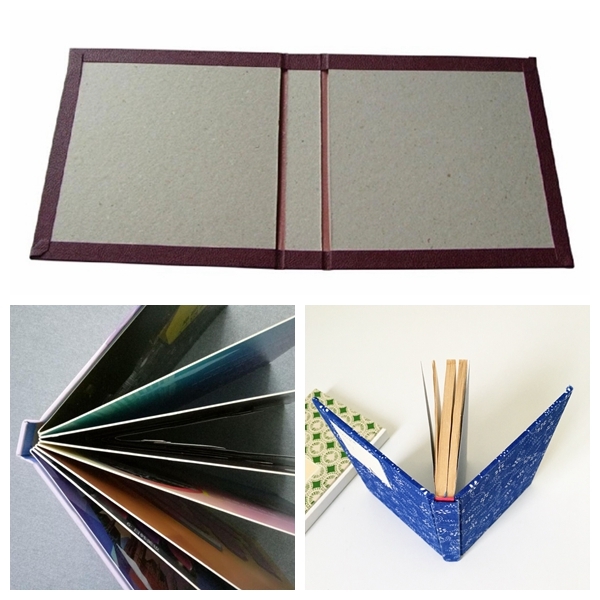

Quickly change and add spine guides to make multiple hard cover products.

It can produce butterfly-fold binding books and calendar stands with simple accessories. |

|

Vacuum table provide big suction that ensures the cover paper not easy to move.

Soft light box for accurate registration of glued covers by specular reflection. |

|

The corner cutter can cut four standard corners on different thickness of cardboard without adjustment. |

|

Equipped with high load casters, it is convenient for level adjusting, fixing and moving the machine. |

Detailed Data:

|

Model |

SK840A |

SK960A |

|

Max. size of product |

840x480mm |

960x480mm |

|

Working table size |

980x466mm |

1090x466mm |

|

Gluing width |

500mm |

500mm |

|

Hardcover edge width |

840mm |

960mm |

|

Cardboard thickness |

1.5 – 4mm |

1.5 – 4mm |

|

Cover paper thickness |

80 – 400gsm |

80 – 400gsm |

|

Power supply |

220V |

220V |

|

Machine gas |

0.6MPa |

0.6MPa |

|

Machine weight |

500kg |

545kg |

|

Machine dimensions |

1650x1460x1110mm |

1760x1460x1110mm |

|

※ Machine air source for selecting, equipment reserved Φ8mm trachea interface. |

||

Sample for Book case making machine

Video

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine.We are your best selection for printing and packaging industries.

In past ten years, Lanxi Jinhua Machine Company is Focusing on machine for wire-stitched exercise books, ruled and sheeting, soft and hard cover book.Can manufacture full automatic exercise book making machine, exercise book ruling machine, book sewing machine, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machine.

we also can provide kinds of printing and packaging machine, such as

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine