HL-QSK840 Semi-Automatic Book Case Making Machine features hot-melt cover gluing, cover suction, cardboards feed automatically, corner cutting and reciprocating automatic edge folding and quantitative water filling functions. One single operator can produce high quality and standardized hard covers for hard cover books, albums, ring books, diaries and calendars very fast.

|

|

Position and feed cardboards and spine cardboards automatically by pneumatic control.

Linear guide and electromagnetism air-aspiration device controls the picking and feeding of cardboards. |

|

|

PLC system control the feed position, distance of edge folder and running time, accurately repositioning, fold and press two edges automatically at one time.

High speed optical fiber detection controls the length and position of the paper feeding accurately. |

|

|

Adding the water automatically and the water quantity can be adjusted.

Independent homothermic impermeable heater unit ensure the fast heating up and accurate temperature control. |

|

Applicates glue on the back side of cover paper. Glue rollers, glue tray and peeling pieces adopt copper alloy which makes heat conduction fast and glue application well-distributed. Both the heating type protein glue (hot) and white latex (cold) can be used individually. Glue thickness and temperature can be adjusted as job needs. |

|

|

Lift and lower the top folding rollers by Plug-in type device to adjust the gap for different thickness of cardboards. |

|

|

Edge size can be adjusted. |

|

|

Cardboard air taps can by moved and changed. |

|

|

Self-adaption peeling pieces strip the glued cover papers from the roller without adjusting. |

|

|

Easy and fast to clean the fold rollers by the roller lifting device.

Dust keeper block off the lint and scraps of paper. |

|

|

The corner cutter can cut four standard corners on different thickness of cardboard without adjustment. |

|

|

Vacuum table provide big suction that ensures the cover paper not easy to move. |

|

|

Split type, can enter the elevator, office and habitable room. |

Detailed Data:

|

Max. size of produce |

840x480mm |

Working table size |

980x466mm |

|

Gluing width |

500mm |

Hardcover edge width |

840mm |

|

Cardboard thickness |

1.5 – 4mm |

Cover paper thickness |

80 – 400gsm |

|

Power supply |

220V |

Machine gas |

0.6MPa |

|

Machine weight |

730kg |

Machine dimensions |

1640x1550x1730mm |

|

※ Machine air source for selecting, equipment reserved Φ8mm trachea interface. ※ Standard 10mm long paper guide, different width and length spine guides can be chose. ※ Reserve the right to change the parameters without prior notice. |

|||

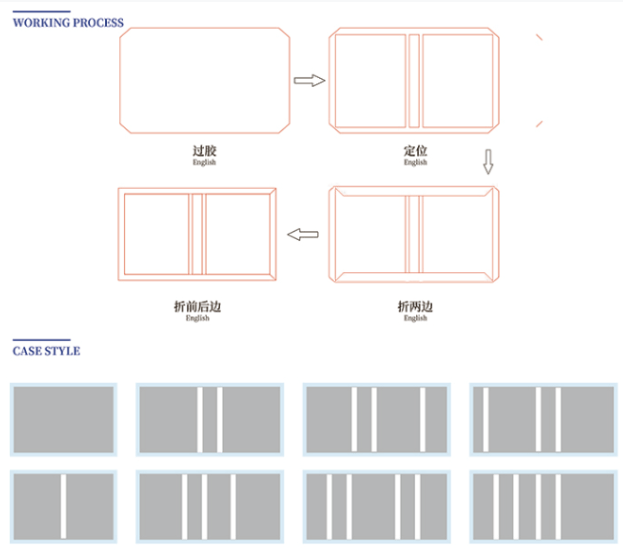

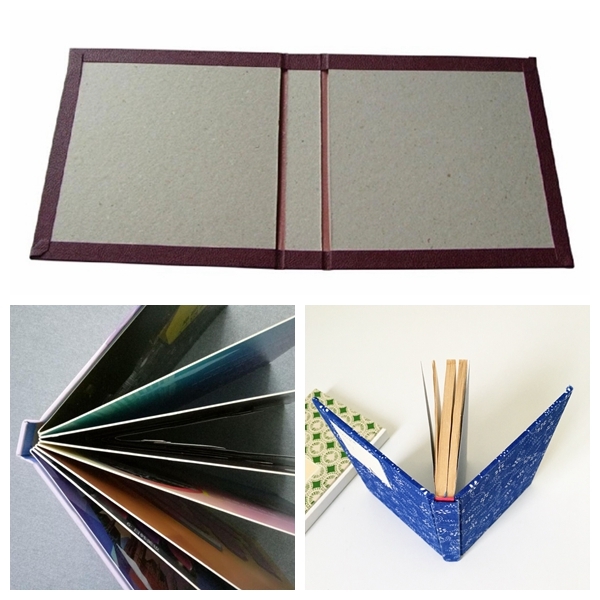

Sample for Book case making machine

Sample for Book case making machine

Video

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine.We are your best selection for printing and packaging industries.

In past ten years, Lanxi Jinhua Machine Company is Focusing on machine for wire-stitched exercise books, ruled and sheeting, soft and hard cover book.Can manufacture full automatic exercise book making machine, exercise book ruling machine, book sewing machine, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machine.

we also can provide kinds of printing and packaging machine, such as

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine