HL-M450A/550A/600A Full automatic Hard cover Making Machine is equipped with automatic feeder and paperboard automatic positioning device, ultrasonic double-sheet detection and pneumatic control pressure angle function, desktop stack transport and discharge, and the operation is quick and convenient. It is the latest equipment for making hardcover book cases, notebooks, covers, calendars, folders, and more.

1. The feeder of this machine adopts the automatic paper feeding structure and it is fully pneumatically controlled. The structure is simple and reasonable.

2. The width adjustment of the stacking platform and the paper-feeding platform adopts center concentric adjustment, and the operation is simple and error-free.

3. The newly designed copper scraper is used in the gluing section to effectively prevent paper-rolling and ensure the normal operation of the machine.

4. It adopts imported ultrasonic double-sheet detection device, which has simple operation setup and effectively prevents double-sheets feeding.

5 The cardboard feeder uses linear guides and is accurate.

6. There is cardboard automatic stop device in the cardboard feeding table if there is a lack of paper, reducing the product scrap rate.

7. The conveyor belt adopts high-power suction fan to make the paper transport more stable and accurate.

8. The paper conveying and positioning system adopts imported high-precision photoelectric control device to make the positioning of paper and paperboard more accurate and reliable.

9. The rear automatic edge folding machine adopts a unique automatic crimping and pressing mechanism to ensure the qualified rate of finished products.

10. The receiving platform adopts a desktop stack for feeding and discharging, which makes it easier to receive materials.

Detailed Data:

| Model No. | HL-M450A | HL-M540A | HL-M600A |

| paper sheet size(A×B) | MIN: 130×230mm

MAX: 480×830mm |

MIN: 130×230mm

MAX: 570×1030mm |

MIN: 130×230mm

MAX: 630×1030mm |

| Paper thickness | 100~200g/m2 | 100~200g/m2 | 100~200g/m2 |

| Cardboard thickness(T) | 1~3mm | 1~3mm | 1~3mm |

| finished product size(W×L) | MIN: 100×200mm

MAX: 450×800mm |

MIN: 100×200mm

MAX: 540×1000mm |

MIN: 100×200mm

MAX: 600×1000mm |

| spine(S) | 10mm | 10mm | 10mm |

| Folded paper size(R) | 10~18mm | 10~18mm | 10~18mm |

| Max quantity of cardboard | 6pieces | 6pieces | 6pieces |

| Precision | ±0.50mm | ±0.50mm | ±0.50mm |

| Speed | ≦25sheets/min | ≦25sheets/min | ≦25sheets/min |

| Motor power | 5kw/380v 3phase | 5kw/380v 3phase | 5kw/380v 3phase |

| Heater power | 6kw | 6kw | 6kw |

| Weight | 3000kg/3200kg | 3500kg/3900kg | 3700kg/4200kg |

| Machine dimension | L8200*W2200*H1600mmx | L9000*W2300*H1600mm | L9000*W2400*H1600mm |

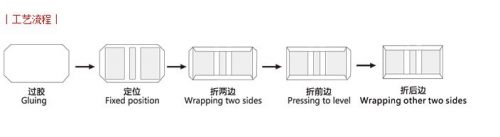

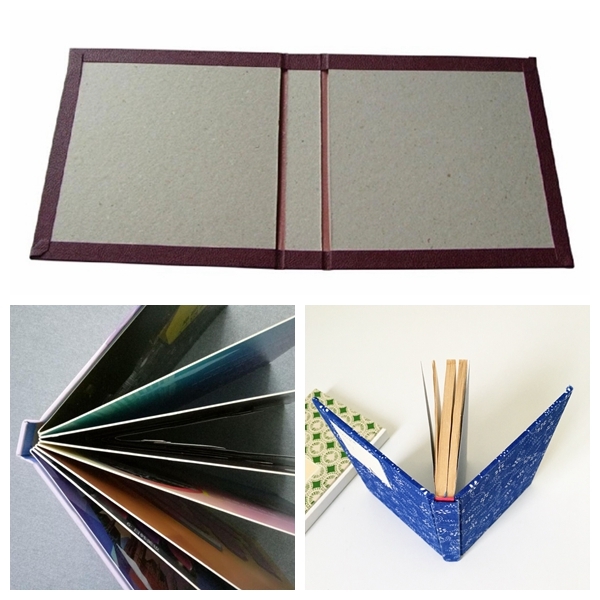

Sample for HL-M450A/550A/600A Full automatic Hard cover Making MachineBook case making machine

Video of HL-M450A/550A/600A Full automatic Hard cover Making Machine

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine.We are your best selection for printing and packaging industries.

In past ten years, Lanxi Jinhua Machine Company is Focusing on machine for wire-stitched exercise books, ruled and sheeting, soft and hard cover book.Can manufacture full automatic exercise book making machine, exercise book ruling machine, book sewing machine, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machine.

we also can provide kinds of printing and packaging machine, such as

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine